Corvex

Corvex Connected Worker is an enterprise IoT SaaS platform for operational excellence, facilitating connectivity and activity management within dynamic environments through AI and machine learning. It includes a web application, mobile application, and diverse IoT hardware components used by tens of thousands of frontline workers everyday.

How I Contributed. MVP & Feature Definition | Roadmap Management | Product Design & Design System Ownership | Stakeholder Management

The platform consisted of a web application, native application and various IoT hardware to elevate user expience.

The Problem Opportunity.

Studies show that at least 70% of the frontline industrial workforce is not engaged.

Discovery.

Comprehensive industry research coupled with an empathetic, hands-on understanding of our user base, was crucial in discovering value.

We dedicated countless hours immersing ourselves in the environments where the work takes place. Whether navigating active construction sites, dynamic manufacturing facilities, or other hands-on settings, these experiences were vital in helping us identify the points of “process friction” (friction reveals value) within operational workflows. We uncovered a few critical KPI areas that carried immense value across industries.

1. Disconnect Between Management and the Frontline

Managers typically lack firsthand experience of day-to-day operations, leading to inefficiencies or misaligned priorities.

Frontline workers often feel disconnected from organizational goals or decisions.

2. Safety and Well-Being

Hazardous work conditions necessitate stringent safety measures.

Mental health and work-life balance are becoming increasingly relevant concerns.

3. Labor Shortages

Aging workforce and difficulty attracting younger generations to industrial jobs.

Skills gaps due to rapid technological advancements.

4. Cultural Shift

Modern industrial workplaces must foster inclusivity, collaboration, and innovation to attract and retain talent.

The incoming workforce will expect & embrace technology.

Personas played a vital role in identifying key stakeholders and uncovering consistent "personality traits" that were instrumental in understanding the landscape.

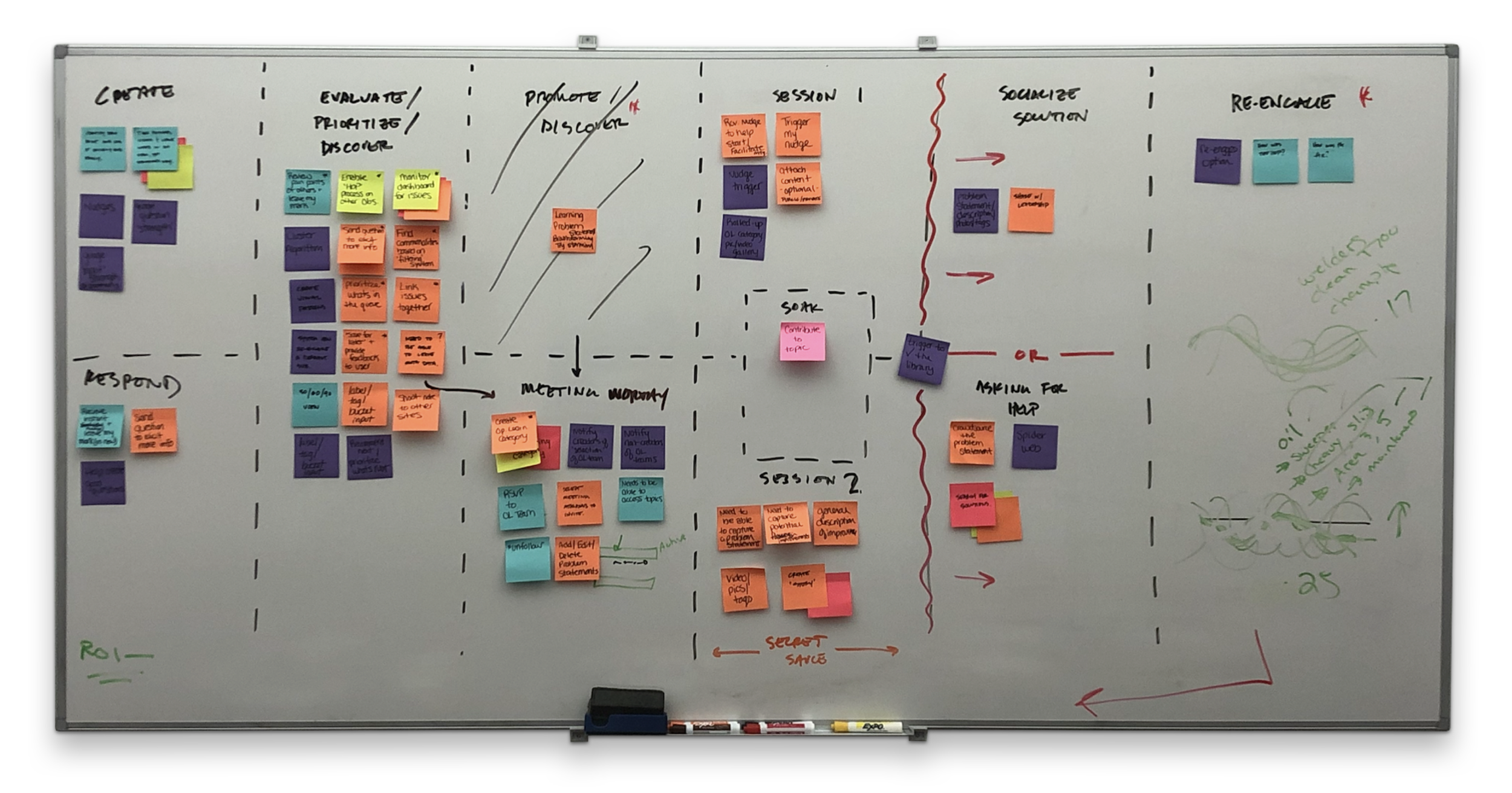

Our process had pillars, but had the ability to adjust for need.

Combining rough sketches with userflows to communicate initial ideas/functionality.

Building Nimble and Adaptive Processes

In a start-up, maintaining forward momentum is crucial for success. The ability to pivot quickly while ensuring thorough validation allows you to continue building a product that aligns with your goals. We focused on a few essential strategies that gave us a competitive edge.

User-Centered, Flexible Approach

In product design, a one-size-fits-all approach doesn’t always work, and this is even more true in a start-up setting where time is often your biggest barrier to success. We couldn’t afford to follow every process or tick every box.

We concentrated on what truly mattered: creating a great experience that captures the voice of the user. Staying deeply user-centered allowed us to assess the real value of our features and adapt accordingly.

Our Objective.

Develop functionality that catalyzes operational transparency, accountability, and action … making complex concepts simple.

The frontline industrial worker is your best sensor. They are the eyes and ears where the work happens.

UI/UX Direction.

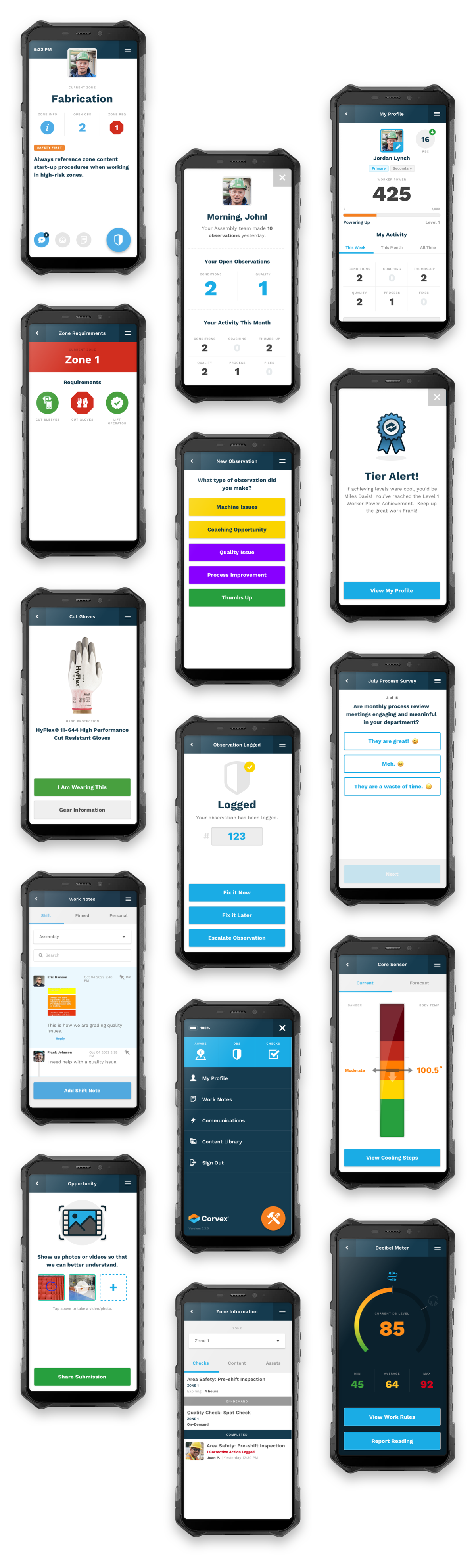

For the Worker.

We developed a straightforward modular design system (called Core) inspired by familiar tools like a wrench or hammer — practical, efficient, and free from unnecessary complexity. The design ensures the tool does exactly what it needs to without hindrance. By creating something relatable, workers could quickly adapt, become proficient, and master it with ease. Our experience pillars:

The tool must be task-based and easy to use.

It should engage workers meaningfully.

The experience of using the tool should provide clear personal benefits to the user.

Workers should feel a sense of ownership in how Corvex is integrated into their workflow.

Our robust on-boarding process in the tool allowed the user to personalize the tool and give them a sense of ownership quickly.

The platform gave workers real-time, contextual information based on their physical location within a work area that they could quickly access relevant things like required safety equipment (PPE), open hazards, rich training/process content, etc.

Our tool facilitated open communication throughout the organization and workers would be continually in the loop around activities.

We empowered workers to quickly document critical observations at the point of work, transforming traditional paper processes and significantly reducing the time needed to resolve issues.

By creating a robust design system, we were able to rapidly prototype and get feature ideas in front of ANY target audience in days, instead of weeks or months.

For the Manager.

Managers often need to make quick decisions but may not have all the data, as well as the time to spend hours on the shop floor for various reasons. By designing functionality that promotes transparency and leverages free-form text submissions, we enabled managers to not only see what’s happening on the frontline but also hear directly from workers.

This approach provides insight into frustrations, ideas, and opportunities for improvement — allowing managers to focus more on solving problems and driving results, rather than managing relationships.

Managers could tailor dashboards to display the data most relevant to their needs, ensuring a focus on what truly matters.

Every element on the dashboard was interactive, allowing managers to quickly explore the underlying reasons behind the data presentation.

We developed proprietary indices and leveraged AI to deliver real-time health insights for specific areas within the workflow.

Our approach to dashboard design emphasized storytelling and simplifying complexity, making data easy to understand and act upon.

By integrating modern techniques such as natural language processing engines, we enhanced the depth and clarity of real-time data analysis and presentation.

Gnarly Challenges.

3 ways building an enterprise SaaS system to support an entire operation was a son of a gun.

1.

Communication and collaboration are EXTRA essential for successful feature development in a start-up.

In a startup environment, things move at lightning speed, and pivots are not just expected — they’re often necessary, no matter how “great” you think your solution is. What helped us evolve and grow effectively was clear and consistent communication and collaboration, both within the team and with existing and prospective customers. This alignment ensures everyone stays on the same page and that the platform's value is regularly evaluated and refined.

Mitigation.

Design Thinking & Focus Groups - I organized and facilitated numerous design thinking sessions with internal stakeholders and conducted multi-level focus groups with the customer base. These sessions were instrumental in uncovering the features that would provide the most value for both the business and every persona in our user base.

Design Systems - Developing a robust design system became one of the most crucial steps in the process. Early on, I realized the importance of moving quickly while presenting customers with high-fidelity, realistic prototypes they could visualize and respond to effectively. This approach enabled rapid iteration and facilitated validation of our ideas both internally and externally.

Results of an “experience map” session around some critical new functionality.

2.

Both workers and managers have faced frustrating experiences with crappy solutions and operate under the legacy of Taylorism.

Both frontline workers and managers have encountered technology that fell short of expectations. We quickly realized that many solutions failed to provide sufficient value, lacked reliability, or required excessive time to implement and learn for everyone involved. Additionally, Taylorism continues to prevail in many industrial environments and managers and workers fail to connect at basic human levels at the point of work.

Mitigation.

Discovery w/Empathy - We immersed ourselves in the field, practicing empathy with our personas. I personally spent a mountain of time on the shop floor, observing and learning how individuals perform their jobs, shadowing their workflows and asking questions along the way. This approach not only helped me identify meaningful ways to enhance functionality but also revealed opportunities to foster transparency, accountability, and action — key elements everyone was seeking.

Creating Transparency - By elevating the voice of the frontline, managers and executives gained immediate and actionable insights into the daily challenges their teams face. Paper-based processes, which once served as lagging indicators of safety and quality, were transformed into leading indicators that fueled AI and machine learning systems.

Out on the shop floor observing how the work happens and the integration of technology.

3.

Keeping momentum is key and smart behavioral economics integration can be a catalyst.

Users onboarded quickly and almost instantly would create observations around frustrations points and friction. This created a lot of data for managers to handle because those workers hadn’t previously felt equipped to solve the problems they documented. With our tool, fixing problems was encouraged because of the transparency that the lifecycle of the observation created.

Mitigation.

Behavioral Economics - We created functionality around incentives and loyalty that ensured that users were rewarded for participation with points. Every action in the tool could have a point value (or no value) and that gave workers an immediate understanding of where they stood in the operational ecosystem. In short, it poured gasoline on everything.

Change Management - Quickly, we learned that change management was a huge part of the puzzle in these organizations. Workers and managers alike were resistant to change and we developed a roadmap that helped everyone understand the path to operational excellence, which they all were seeking. We called this “The Corvex Journey”.

Fully customizable achievement tiers and points exploded usage.

The Corvex Journey established a process to operational excellence.

Platform Impact.

Our customers realized a transformative ROI from our platform.

Delivered an 85% reduction in recordable safety incidents across entire customer base.

One of our customers achieved a milestone with zero recordable injuries in a calendar year and the lowest TRIR in their history. The only new factor contributing to this newfound success was the deployment and adoption of our tool.

Realized 117% increase in catching defects in critical quality production environments.

Creating quality products was a foundational pillar for each of our customers. Our quality functionality ensured that workers clearly understood expectations and consistently upheld the quality standards required by each business unit.

Returned a 45% increase in asset uptime after adding transparent, cross-functional indicators.

Developing a “digital twin” for any asset enabled our customers to quickly identify areas of success and challenges in production (production = profit). Clear visual indicators provided real-time insights, empowering them to take swift action when issues arose.

Established 98% adoption rate at an enterprise industrial customer supporting thousands of frontline workers daily.

The customer, who is a major industrial manufacturer in the automotive industry, really took hold of our loyalty and achievement functionality. They coupled tangible incentive programs with levels in the tool and workers were able to enjoy the gamified experience to great gain.

From Valued Customers.

If you’ve scrolled this far, take a gander at a few more native app screens.

… and some web app screens.

Featured Work.

Park Tool

Park Tool holds a global leadership position in bike tool manufacturing, yet its digital offerings were overly complex and outdated.